GM's high-level meetings with railroads to get new cars to market faster

General Motors no longer has a backlog of finished new vehicles sitting at factories awaiting a rail car to take them to dealerships — that's good news for car buyers.

GM's factory lots were cleared by the end of last year as a result of a series of CEO-to-CEO- level meetings between the automaker and the six Class 1 railroad companies, said Renee Wawrzynski, GM's executive director of Global Logistics and Containers, GM Purchasing and Supply Chain.

GM presented its new-vehicle production forecasts, along with forecasts it gathered from other carmakers, to the railroads to prove there was a need for the railroads to buy more new rail cars to meet demand and clear out a backlog of tens of thousands of vehicles across the industry stranded at factories due to the massive shortage of rail cars that plagued the auto industry last year, she said.

The railroads committed to add about 400 new rail cars a month to the North America rail system starting late last year. The North America rail network is made up of 170,000 miles of rails, railroad experts said.

With more rail cars entering the network, Wawrzynski said, GM has finally been able to ship those finished new vehicles it had parked at factories, to dealers.

"We’ve gotten much greater, stronger flow of vehicles to them and much more opportunity for the customer to have the vehicles they want to have," Wawrzynski said. "The vehicles we’re building now are getting to them much, much faster than they were last year.”

A fix by the industry for the industry

In fact, the auto industry at large will see improvements in rail transportation this year — albeit at a slow pace. Automotive Logistics Executive Committee (ALEC), a group that represents 16 automakers, including GM, Ford Motor Co., Stellantis and electric vehicle makers Tesla and Rivian, to the railroads, has had meetings last year with the railroad companies and TTX — the company that manages the rail cars, said Bryan Burkhardt, executive director of ALEC.

ALEC shared its collective new-vehicle production forecasts from all automakers with the railroad industry too, pushing the railroads to add rail cars and improve operations, Burkhardt said.

As a result of ALEC automaker-members' production forecasts and the meetings with the railroads, including GM’s efforts, the railroads will add about 5,000 new autoracks to North America this year, Burkhardt said. That's about 400 a month.

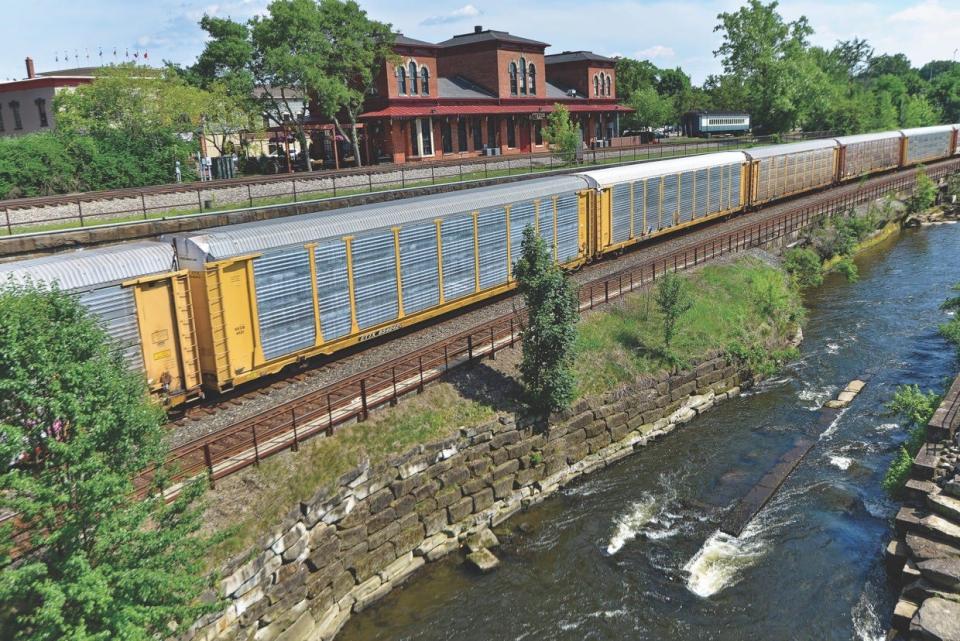

Autoracks are the aluminum-sided rail cars with bi-level and tri-level racks inside used to transport vehicles. The railroads will also improve the network's speed to unload and turn over a rail car faster, known as velocity, so that fewer new autoracks are ultimately needed, Burkhardt said.

Wawrzynski said GM has tracked the railroad velocity and it has improved by a couple of days compared with a year ago.

"There were CEO-to-CEO meetings happening with several automakers and the railroads," Burkhardt told the Detroit Free Press. "I give GM credit for having those meetings, too. The collective pressure of the automakers and the Surface Transportation Board really forced the railroads to pony up and add rail cars. I give credit to GM, but also to Ford, Toyota, Honda and Stellantis. ... Everybody put pressure on the railroads to add capacity."

The making of a crisis

The shortage of autoracks last summer resulted in some 70,000 new vehicles across the industry parked near factories awaiting rail cars for shipment, according to U.S. Surface Transportation Board Chairman Martin Oberman, as reported by the Detroit Free Press last June.

The direct impact of that rail car shortage to U.S.-based suppliers exceeded $350 million, Oberman said, meaning the impact on the U.S. economy could "easily exceed $3.75 billion" if the problem was not corrected, he said.

That's because freight rail moves nearly 75% of new vehicles purchased in the U.S. and carries 1.8 million carloads of motor vehicles and parts at any given time, John Bozzella, CEO of lobbying group Alliance for Automotive Innovation, told the Detroit Free Press last June. The group was "asking the Surface Transportation Board to intervene and make sure the country has a fully functioning freight rail system.”

Alliance for Automotive Innovation spokesperson Brian Weiss said this month that, "The situation (with the rail cars) has improved since the summer, but remains an area of concern for the industry.”

The autorack shortage occurred after the auto industry resumed full new-vehicle production following the COVID-19 shutdown and the shortage of semiconductor chips. The railroads were not ready for the influx of new vehicles that were produced, Wawrzynski said.

"They had not replaced some of their aged fleet and so it led to this shortage of rail cars," Wawrzynski said. "In addition, the network was running slower … so both of those things led to the crisis. We all share the same pool of bi-level and tri-level rail cars."

In a November "Railroad Trends" speech, Oberman said the rail system has improved, but noted that "we still have a long way to go to build up the railroad industry to the point where it can truly compete with the reliability of trucks and, even more importantly, provide the resources American industry needs to grow."

GM, Ford and Stellantis impact

Wawrzynski declined to say how many new vehicles GM had sitting at factories awaiting a rail car for shipment last year, but the backlog was significant enough for CEO Mary Barra to tell NBC News last June: "One of the biggest issues I have right now is logistics. I have vehicles built that I can’t get on a truck or rail to get them to where it needs to go."

Between 70% to 80% of the vehicles that GM builds travels by rail from the factories because it's the most efficient way to ship new cars, Wawrzynski said. That's why GM looked to make "changes to our contracts" and had senior-level discussions with railroad leaders to convey "the criticality of the situation, the impact to our customers and really work to develop a partnership with the railroads."

But Wawrzynski said it was the collective data from all the automakers that convinced the railroads to invest in new autoracks.

Stellantis spokeswoman Jodi Tinson told the Detroit Free Press in an email: "Stellantis has been meeting regularly with the railroads to discuss concerns about their capacity constraints. While actions have been taken to improve the situation within the U.S., the railroads must continue addressing equipment needs to support (automakers) business coming out of Mexico, which has resulted in Stellantis using other means to meet our customers' expectations."

She did not elaborate on those other means, but Burkhardt said, “Every automaker has had to take product that would naturally go by rail and move it either by truck or short sea via Mexico to the United States.”

Going by “short sea” is typically more expensive than railroad, but he said, “ALEC members are having issues with Canada and Mexico with the rails.”

Ford spokesman Lars Weborg also declined to offer specifics, but told the Free Press in an email: "As part of our normal business operations, we regularly engage with representatives from the rail industry."

Still work to be done

Burkhardt said there has been some improvement with several automakers seeing their backlogs of finished new vehicles cleared out since last year. He credits a large part of that to the Christmas plant shutdowns and the UAW strike idling some plants, saying the production halts allowed the railroads to catch up.

GM spokesman Kevin Kelly said the plants that were affected during the strike "were minimal so it wouldn’t be a huge impact.”

"The key message is the railroads have made improvements in the speed of the network, they're adding railroad capacity and expect continued improvement," Burkhardt said. "Everything's moving in the right direction, but at a turtle's pace."

Burkhardt said there are currently 52,000 bi-level auto racks in the TTX fleet in North America. The bi-levels are the most popular in use because they carry the big-selling pickups and SUVs. Based on the data ALEC had, the railroad industry needs to add about 10% more auto racks to manage the automakers' transportation needs this year. TTX did not respond to requests for comment on this article.

"But if (the railroads) have a bunch of crew issues, that will slow the network speed, so then they’d need to add even more rail cars," Burkhardt said. "But if they improve the North American network they’ll need less cars because everything moves faster.”

A 'substantial' investment by railroads

The cost of one new autorack rail car is about $100,000, said Nick Little, director of Railway Education at Michigan State University. He said an autorack rail car can carry 12 to 18 vehicles, depending on the size of the vehicles, whereas a truck hauler carries seven to eight vehicles maximum.

The autoracks are a two-part unit, Little said. The base is a standard flat car, which he estimates costs around $75,000 to make. The interior structure is purpose built in terms of the number of levels needed and other fittings so it could cost $15,000 to $25,000, he said. An autorack rail car should last about 50 years, Little said.

"Because of their relative simplicity and the ability to repurpose flat cars and return some cars to service from storage, I expect six months to a year would be enough time to solve the problem," Little said.

He said the main manufacturers of autoracks are Trinity Industries and The Greenbrier Companies. Trinity did not respond to a request for comment.

But Jack Isselmann, senior vice president of corporate communications at The Greenbrier Companies, told the Detroit Free Press the company is "actively building autoracks" and aims to increase daily output of new autoracks by 80% this year.

Greenbrier, which is the leading manufacturer of freight rail cars for North America, makes the Multi-Max autorack, which allows the deck to be configured as a bi-level or low bi-level to fit various vehicles. The autoracks are built mostly in Mexico and the time to build it depends on the line space available and the parts availability, Isselmann said. Also, it can take some time to transport the new rail cars to the railroad too, he said, so he declined to provide a date by which the new autoracks will be stocked and in use across the network.

Isselmann also declined to confirm whether that increase is 5,000 new autoracks or reveal the cost to make one of them, but he said: “It’s been several years since we’ve seen this level of demand. We’re seeing a very encouraging auto-by-rail market and the railroads have invested substantially to move finished automobiles by rail and we intend to be there to help support their investment.”

The railroads say they are adding rail cars

The Class 1 railroads — those with annual revenue over $250 million — include CSX, Union Pacific, BNSF, Norfolk Southern, Canadian National and Canadian Pacific Kansas City.

The Detroit Free Press reached out to them, but only Norfolk Southern and Canadian National (CN) responded with comment. Norfolk Southern spokeswoman Katie Byrd said in a January email that "Norfolk Southern is focused on improving fluidity and increasing network velocity for our customers."

To do that, she said, the railroad coordinates on an annual basis with other Class 1 railroads to collectively look at forecast volume and service metrics to adequately prepare and meet demand. She said Norfolk Southern has added autorack cars to its fleet.

"We strengthened our multi-level fleet in 2023 and have plans to secure even more multi-levels by the end of 2024," Byrd said. "We are working to reposition empty multi-level cars more efficiently, cut down on the average cycle time, and prioritize railcars in need of maintenance."

She said last year the company "reactivated" two repair shops and added two online repair shops. It also secured repair space at three additional offline shops, and added manpower at three Norfolk Southern origin ramps to handle additional repairs to the rail cars to keep them operational.

CN serves 13 North American vehicle assembly plants and handles more than 2.4 million finished vehicles annually, spokesman Scott Brown said in an email.

"We partner with our customers, including GM, to help them grow their business," Brown said. "Our new investments in automotive fleet capacity will help our partners respond to increased consumer demand now, and in the future."

And that's where the real benefit lies in the end: with the car buyer.

“It’s really a benefit to the customers because as you drive by the dealerships you can tell from where we were a year go to now, how much more full they are," GM's Wawrzynski said. "That just gives people the ability to get a vehicle when they want or need one, and those who ordered them are going to get them much faster than they would have a year ago.”

More: GM and Honda start commercial production of hydrogen fuel cells in Michigan

More: Jeep plans to ax Renegade in US and Canada, focus on larger SUVs, EVs

Contact Jamie L. LaReau: jlareau@freepress.com. Follow her on Twitter @jlareauan. Read more on General Motors and sign up for our autos newsletter. Become a subscriber.

This article originally appeared on Detroit Free Press: Railroad investment to help GM get new vehicles to market faster